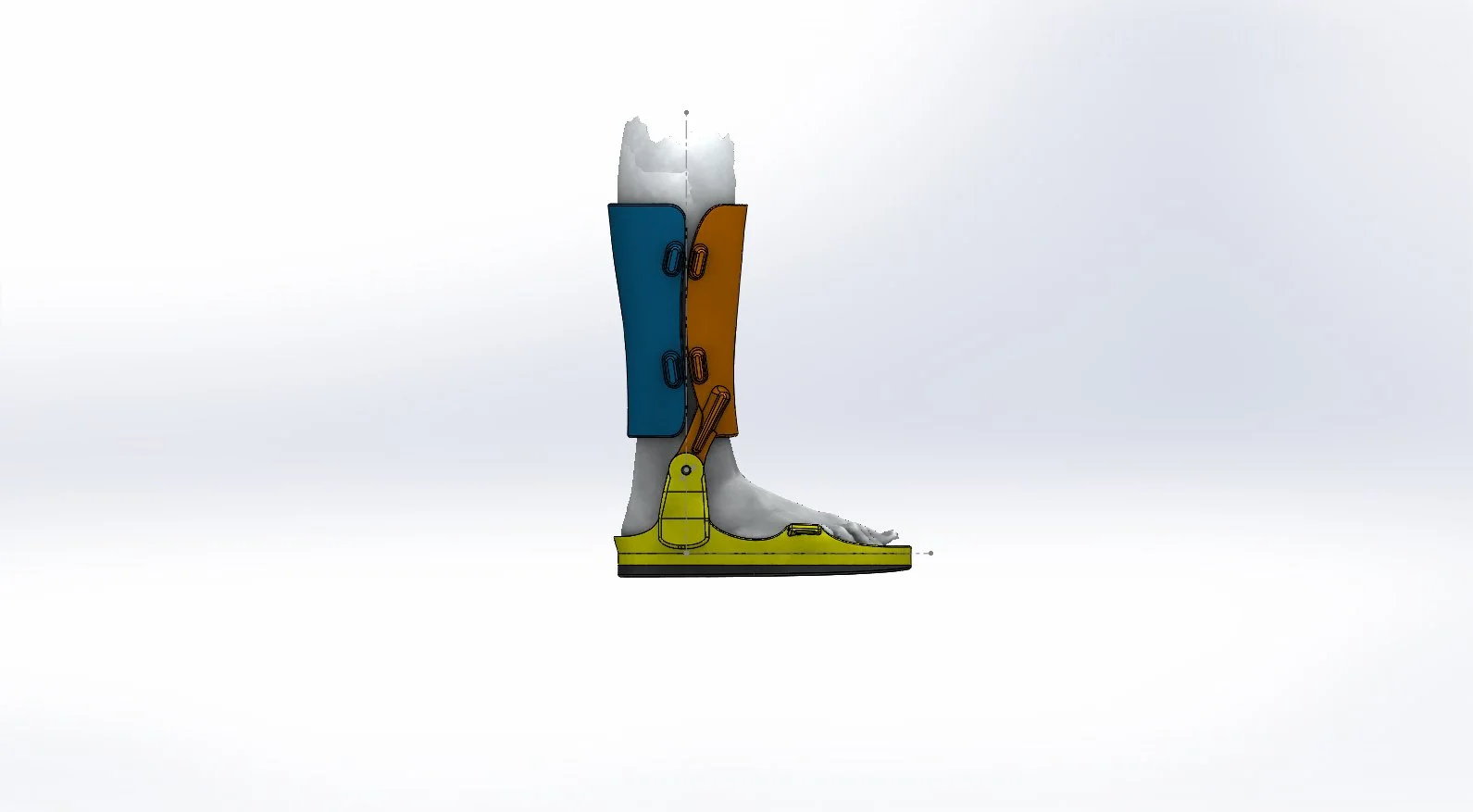

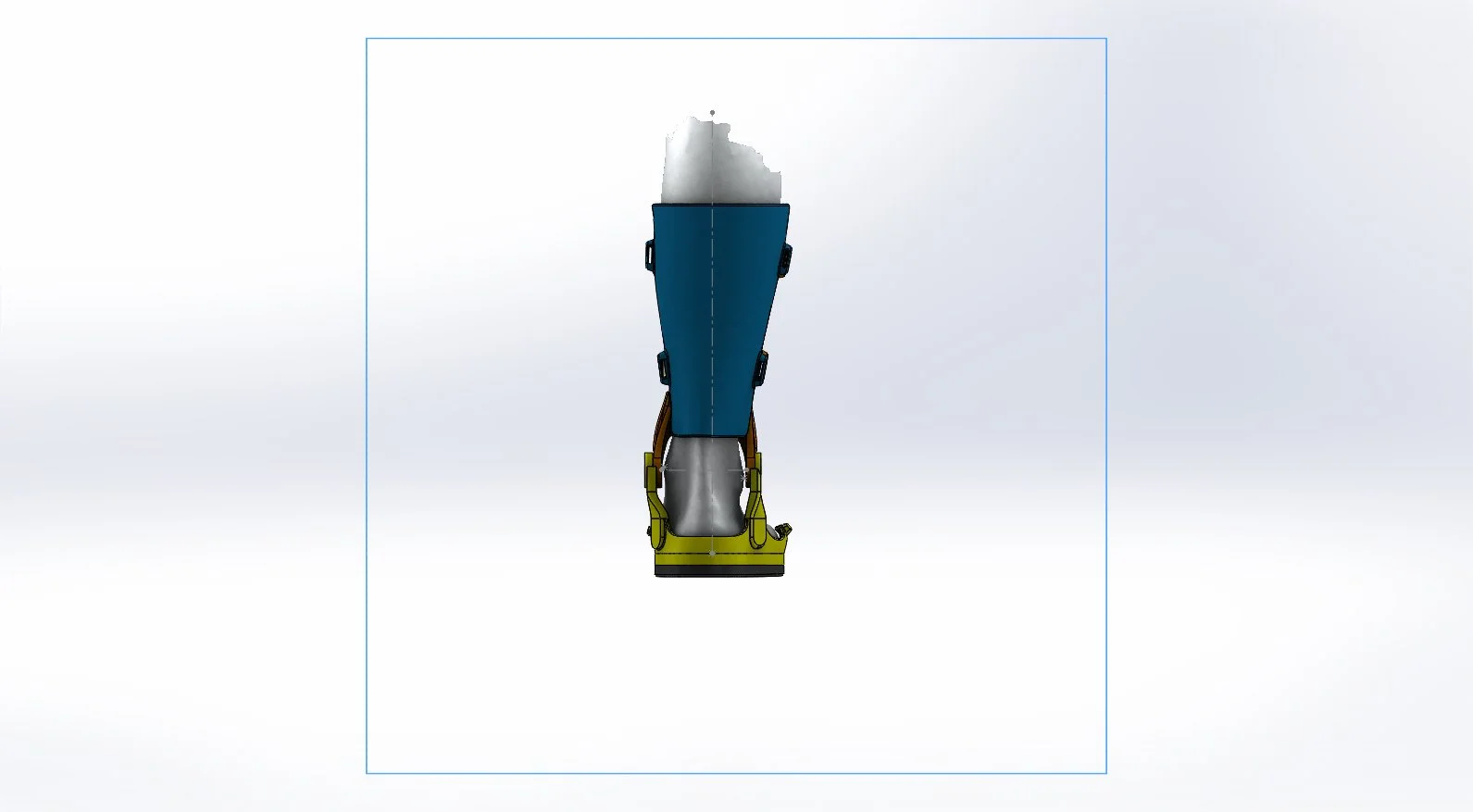

ORTHOPEDIC BOOT

CLIENT:

Independent.

CHALLENGE:

A patient required their ankle to be fixed at a particular angle which needed adjustments over time.

The standard method was forming a cast over the ankle at the required angle, and then replacing the cast at a new angle after a specified period. The cast makes mobility difficult and cannot be removed until it is replaced.

PROCESS:

Scan the ankle to get accurate 3D data to design a purpose-fit boot. The design incorporated an adjustment to a swivel point in the boot, allowing precise and gradual adjustments. A high point was added to the sole to allow the foot to roll enabling near-normal walking. The boot was plastic 3D printed with a laser-cut stainless steel adjustment mechanism. The rubber 3D-printed high point improved traction while walking.

SOLUTION:

The boot was comfortable and improved mobility while allowing flexibility in angle adjustment. The boot was able to be removed when necessary.